Others

Treatments

In the post-harvesting of tubers, mushrooms and fruits such as persimmon, melon and watermelon, bananas, the washing1 is a critical point for the control of control ofrotting2 and food food safety3 The inactivation or reduction of pathogenic microorganisms must be achieved.

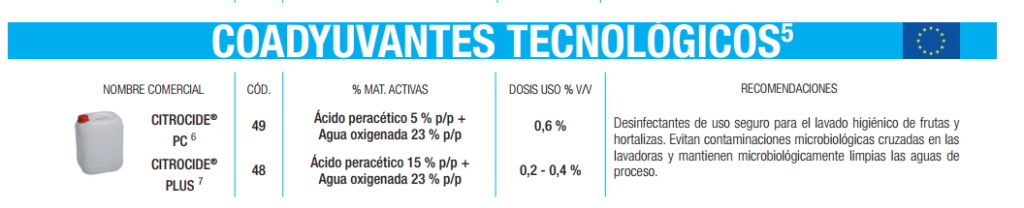

1.- Post-harvest washing is carried out with the CITROCIDE® SYSTEM®System, which monitors and controls, continuously and automatically, the concentration of Citrocide® PC and Citrocide® PLUS formulations in the wash water, maintaining the optimum dosage to achieve maximum efficacy at all times.

Our formulations are biocides; substances that are environmentally friendly and harmless to human health. Their use is authorized by AECOSAN as a technological adjuvant and certified as an input for organic agriculture.

The CITROCIDE® SYSTEM acts as a "firewall", converting the washing machine into a Critical Control Point (CCP) to avoid cross-contamination, improve food safety and reduce surface contamination, thus avoiding losses due to spoilage of these products. With our system we achieve the inactivation or reduction of microorganisms potentially pathogenic for the product and for humans, with the objective of minimizing cross-contamination and reducing spoilage.

Our formulations significantly reduce surface contamination by bacteria, fungi and yeasts present before and after being washed either with potable water to be wasted or with the Citrocide® System.

Keeping the wash water free of any microorganisms allows for its safe recycling, which saves significant amounts of water in the washing process and reduces the industry's water footprint.

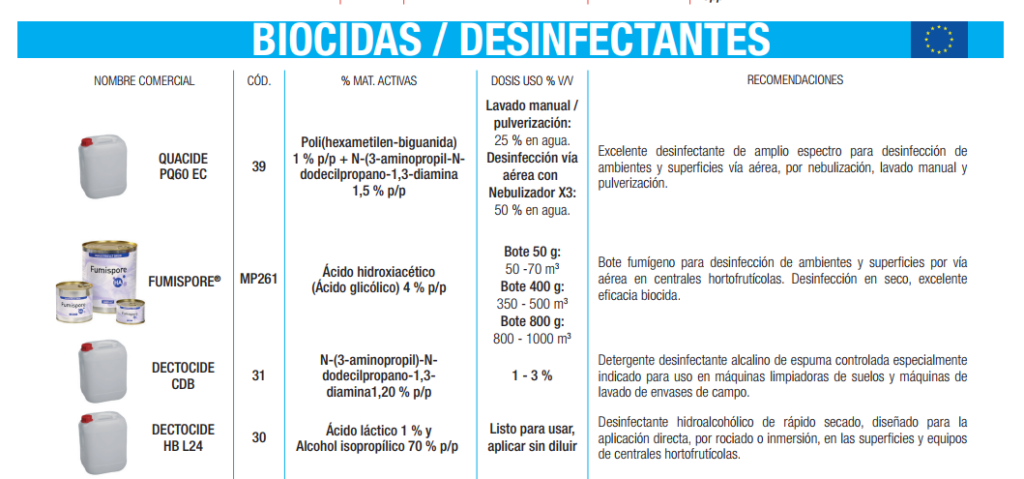

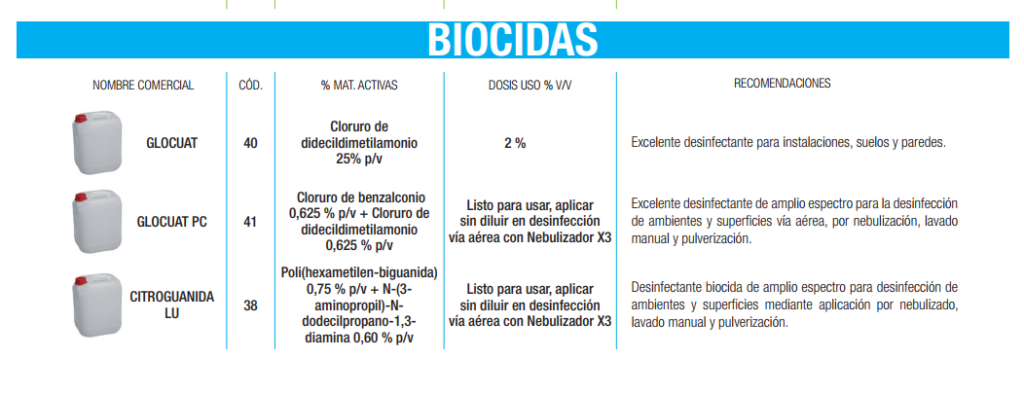

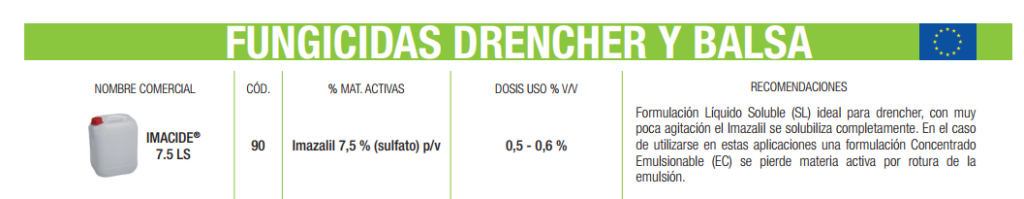

Cleaning and disinfection

Decrease inoculum levels1 in the different areas of the Central Fruit and Vegetable Processing Plant, as well as in the drawers2 and especially in the cold storage rooms is essential for the control of spoilage, since the fruit spends a large part of the time in them, and therefore poses a greater risk of contamination.

1.- Maintaining the hygiene of the fruit and vegetable plant (CH) and its elements is essential for the control of rotting in fruits and vegetables.

The establishment and application of a correct Cleaning and Disinfection (C&D) program in the plant leads to a significant improvement in the results of rot control and avoids the risk of cross contamination by microorganisms pathogenic to human health.

In this regard, cleaning and disinfection of cold storage rooms is crucial as they can be a reservoir of fungicide-resistant spores.

2.- Field containers can constitute an important reservoir of pathogen inoculum, since their continuous reuse makes them important vectors/transmitters of these pathogens, so any L&D program must include an efficient protocol for their washing.

Transportation

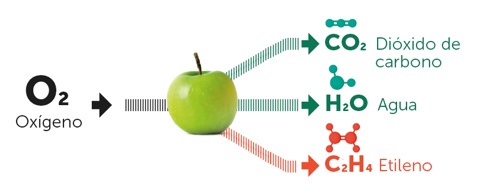

From shipping and during transport, fruits are living beings that continue to breathe after harvesting. As they breathe, they produce carbon dioxide (CO2), water (H2O) and ethylene (C2H4). The elimination of ethylene1 during transport provides us with additional safety to achieve good arrivals at destination. Being the elimination of ethylene of special relevance for persimmons, melons, watermelons and bananas.

Ethylene is a gaseous hormone that all vegetables synthesize. This hormone regulates the processes associated with ripening and senescence of fruits and vegetables, so its control is essential to modulate the ripening process of fruits.

The accumulation of this gas causes accelerated ripening and, therefore, has an impact on the loss of quality and reduction of shelf life, which is usually manifested by the loss of pulp firmness.

Ethylene is eliminated through an absorbent that also absorbs the volatile organic compounds responsible for odors and slows ripening.