Stone fruit

Treatments

There is a wide variability of stone fruit postharvest practices. Depending on the type of cultivar and the packing lines of each customer, hydrocoolers1 and/or water dumpers1 are used to reduce the temperature of the pulp and to avoid mechanical damage during dumping. Temperature is a factor of great influence on the postharvest life of these fruits, reducing the respiratory rate and transpiration, and sometimes fungicide treatments 2 are also applied to prevent the appearance of rot and extend the shelf life.

Therefore, it is essential to properly characterize the operation of each system in order to achieve a good result.

Washing is a critical point for the control of spoilage and food safety, as it must ensure the elimination of pathogenic microorganisms for stone fruit and for humans, with the aim of avoiding cross-contamination and reducing spoilage.

Citrocide® PC and Citrocide® PLUS are broad spectrum biocides that control pathogenic fungi, bacteria, yeasts and viruses. Their use is authorized by AECOSAN as a technological adjuvant and certified as an input for organic agriculture.

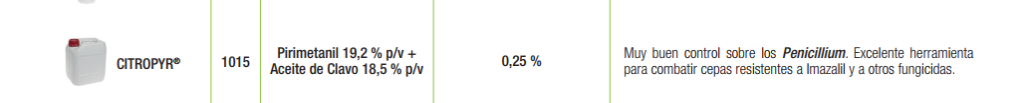

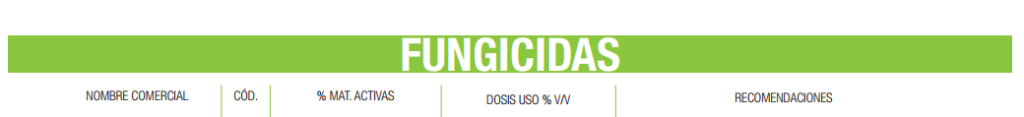

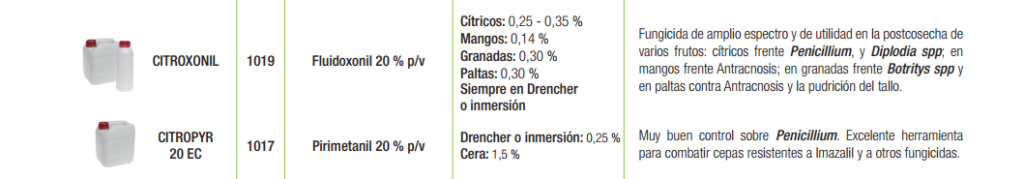

2.- Each target fruit has its own Maximum Residue Limits (MRLs) depending on the country of destination. Consult with our technical team which is the best fungicide solution available for your crop.

Cleaning and disinfection

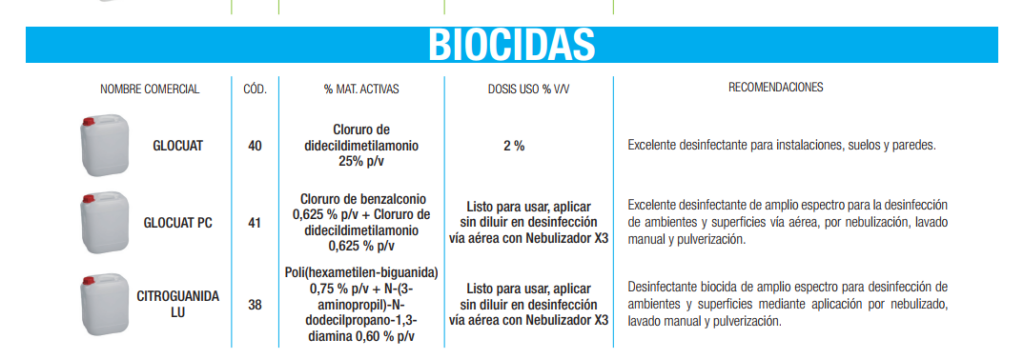

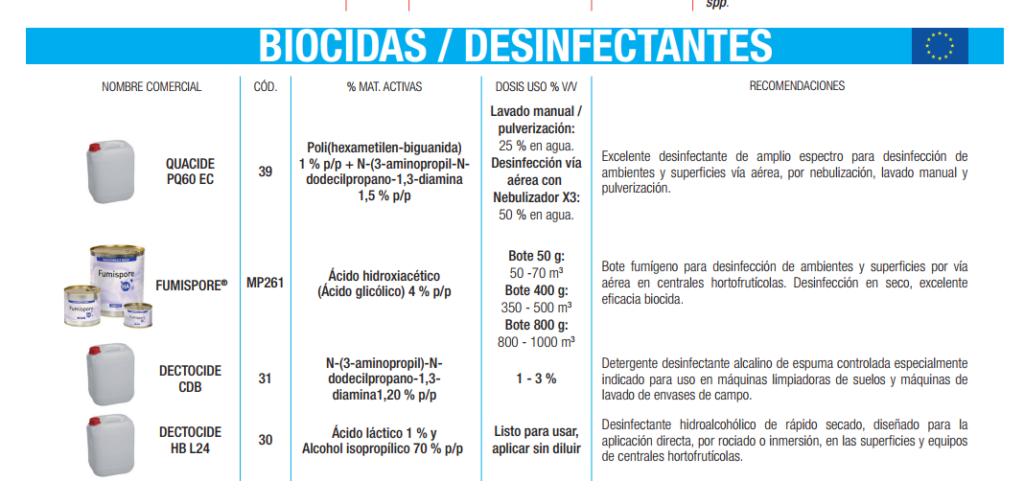

Reducing inoculum levels1 in the different areas of the Central Fruit and Vegetable Processing Plant, as well as in the crates2 and in the cold storage chambers is essential for the control of spoilage, since fruit can spend a long time in them, increasing the risk of contamination.

1.- The maintenance of the hygiene of the fruit and vegetable plant (CH) and its elements is essential for the control of rotting in stone fruit.

The establishment and application of a correct Cleaning and Disinfection (C&D) program in the plant leads to a significant improvement in the results of rot control and avoids the risk of cross contamination by microorganisms pathogenic to human health.

2.- Field containers can constitute an important reservoir of pathogen inoculum. Any L&D program should include an efficient protocol for their washing and disinfection.

Transportation

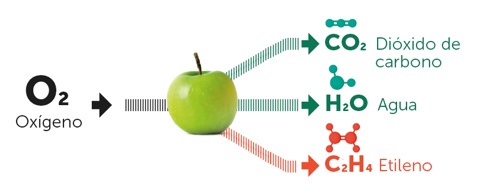

From shipping and during transport, fruits are living beings that continue to breathe after harvest. As they breathe, they produce carbon dioxide (CO2), water (H2O) and ethylene (C2H4). The elimination of ethylene1 during transport provides us with additional security for good arrival at destination.

Ethylene is a gaseous hormone that all vegetables synthesize. This hormone regulates the processes associated with ripening and senescence of fruits and vegetables, so its control is essential to modulate the ripening process of climacteric fruits.

The accumulation of this gas causes accelerated ripening and, therefore, has an impact on the loss of quality and reduction of shelf life, which is usually manifested by the loss of pulp firmness.

In addition, it has been shown that, in some stone fruit species, inhibiting the action of ethylene can reduce flesh browning and chilling injury.

Ethylene is eliminated through an absorbent that also absorbs the volatile organic compounds responsible for odors and slows ripening.