Tropical

Treatment

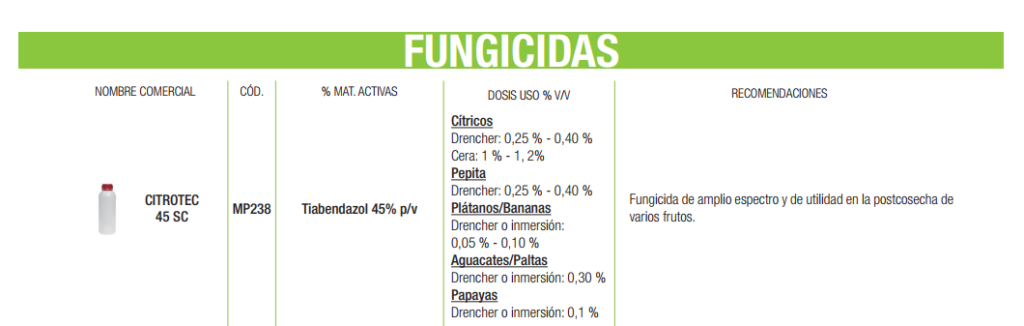

The application of the most appropriate postharvest treatments1, as a rule within the first 24 hours after harvesting, is the main strategy to avoid rotting, which, together with chilling injury and weight loss, is one of the main causes of postharvest losses in tropical fruits.

In the cases in which a treatment is carried out, it must be in aqueous medium, as they are the best to achieve a perfect wetting of the fruits.

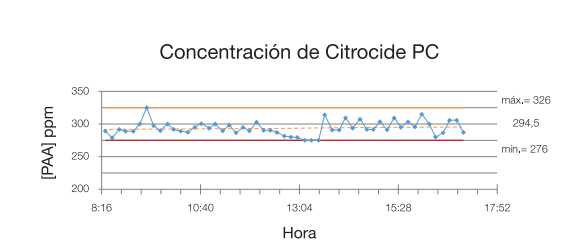

With the CITROSOL VERTIDO CERO® System2 and our technical support3, we are able to maintain the initial efficacy of the treatment in Drencher, Drencher online or basin, since it keeps the fungicide broths unaltered and the residue levels homogeneous.

Variability in application systems results in variable results in rot control and in the level of residues in the fruit. Our CITROSOL DS dosing equipment maintains unaltered the initial efficacy of the treatment broths.

The CITROSOL VERTIDO CERO® System allows the recovery of the broth from the drenchers and the reduction of suspended solids, without affecting the concentrations of fungicides, coadjuvants and biostimulants, which we manage to keep constant.

ZERO DISCHARGE SYSTEM CITROSOL

DRENCHER'S BROTH 4865 TREATED PALLETS

CONVENTIONAL SYSTEM

DRENCHER'S BROTH 200 TREATED PALLETS

On-line treatment

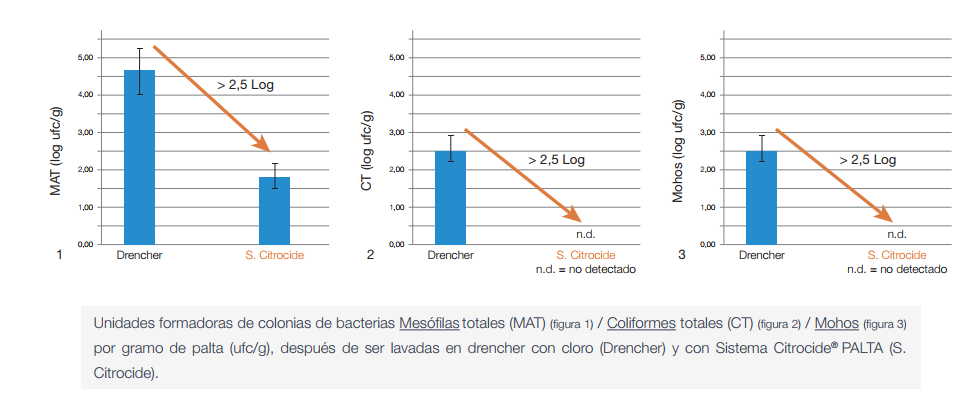

This system is a guarantee of food safety, as we can see in these three graphs where we represent the effectiveness of the system in the surface disinfection of avocado, Hass variety (studies conducted by CNTA-Peru in Chincha, August 2016).

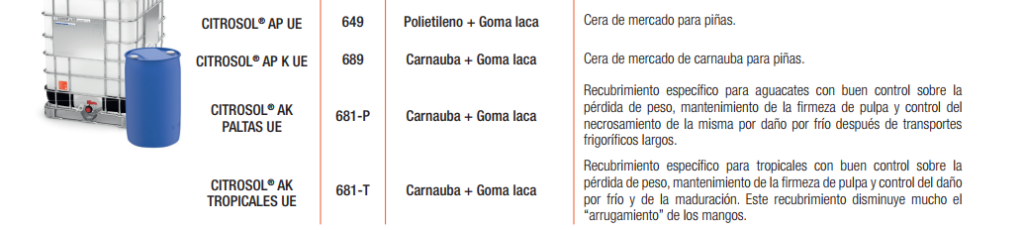

Waxing is carried out once the fruit is dry with a system composed of rotating heads and brushes that allow a homogeneous application and guarantee an efficient coating, without excess product and an excellent visual appearance.

The main waxes for tropicals are CITROSOL AK Tropical EU which has been developed to increase the shelf life of tropical fruits such as mangoes, and CITROSOL AK Avocado EU developed to extend the shelf life of avocado. These coatings control weight loss in avocados and mangoes more than other available waxes, delay the climacteric peak, and decrease ethylene production and respiration rates in avocados. In the case of mangoes, "shriveling" was greatly reduced by waxing.

The effects on ethylene production and respiration induce a delay in ripening, maintaining fruit firmness and some delay in color development; the delay in ripening increases resistance to pathogenic fungi. The two coatings CITROSOL AK Avocado EU and CITROSOL AK Tropical EU reduced rotting and chilling injury in avocados and mangoes, respectively. All of the above was verified in an experimental study conducted by the Department of Postharvest Science of Fresh Produce, of the Agricultural Research Organization, Volcani Center (ISRAEL) in 2018.

We have also developed CITROSOL AP UE and CITROSOL AP K UE, two specific coatings for pineapples with very good control of weight loss, pulp firmness and the incidence of sunken and/or dried out spots (DPA), while allowing a natural evolution of color change.

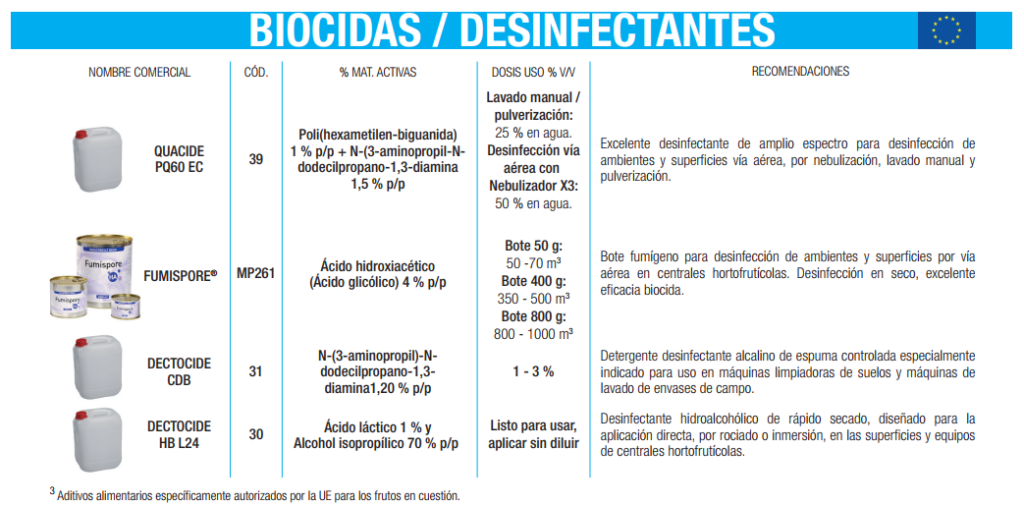

Cleaning and disinfection

Reducing the levels of inoculum1 in the different areas of the Central Fruit and Vegetable Processing Plant, as well as in the crates2 and in the cold storage chambers is essential for the control of spoilage, since the fruit can spend time in them, increasing the risk of contamination.

1.- Maintaining the hygiene of the fruit and vegetable plant (CH) and its elements is essential for the control of rotting in tropical fruits.

The establishment and application of a correct Cleaning and Disinfection (C&D) program in the plant leads to a significant improvement in the results of rot control and avoids the risk of cross contamination by microorganisms pathogenic to human health.

2.- Field containers can constitute an important reservoir of pathogen inoculum, especially resistant inoculum. Any L&D program should include an efficient protocol for washing and disinfection.

Transportation

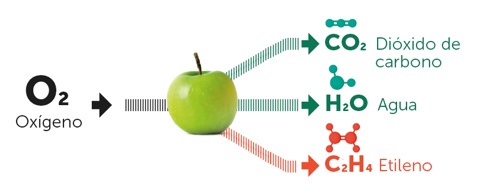

From shipment and during transport, tropical fruits are living beings that continue to breathe after harvest. As they breathe, they produce carbon dioxide (CO2), water (H2O) and ethylene (C2H4). The elimination of ethylene1 during transport provides us with additional security for good arrival at destination.

Ethylene is a gaseous hormone that all vegetables synthesize. This hormone regulates the processes associated with ripening and senescence of fruits and vegetables.

The accumulation of this gas causes, in tropical fruits, loss of commercial quality and a decrease in their useful life.

Ethylene is eliminated through an absorbent that also absorbs the volatile organic compounds responsible for odors and slows ripening.