Eco-Bio

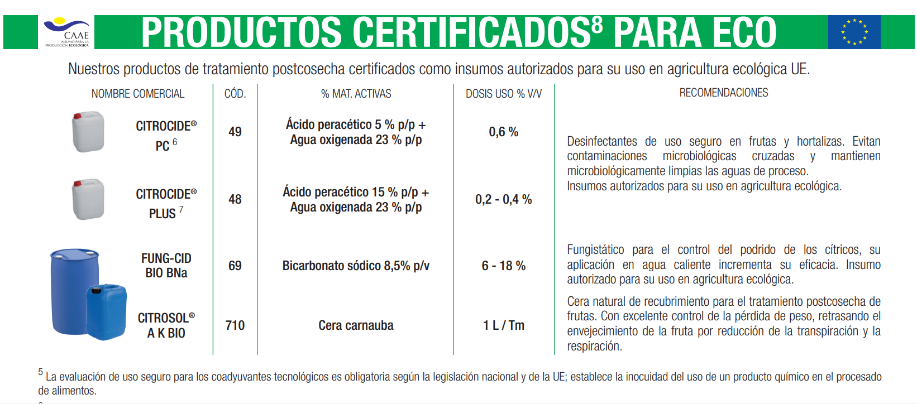

BIOCARE is the first complete range of products for citrus fruit postharvest treatment certified as organic inputs. It covers all phases of the citrus fruit postharvest process with a fungistaticfor rot control 1, a technological adjuvant for washing 2 and a natural waxy coating 3.

In other fruit and vegetable products, postharvest washing 4 is a critical point in the control of spoilage and food safety.

Certified for use in Organic Agriculture:

CAAE Certificate of Conformity Document Number CE-005644-2019

This certification is issued on the basis of the European organic production standards (Regulation (EC) 834/2007 on organic production and labeling of organic products), therefore, it is valid for any organic operator certified under these standards both in Europe and in third countries.

FUNG-CID BIO BNa is a specific fungistatic for the control of citrus rot that increases its shelf life. This input has broad spectrum antimicrobial properties, making its use in post-harvest treatments an effective tool for rot control in organic production.

The application is carried out in aqueous medium in a drencher system, by immersion or in Drench online with our CITROSOL DS dosing equipment, with which we manage to maintain unaltered the initial efficacy of the treatment broths.

Our formulations Citrocide® PC and Citrocide® Plus are broad-spectrum biocides that control fungi, bacteria, yeasts and viruses. Their decomposition products are water and acetic acid, substances that are environmentally friendly and harmless to human health. Its use is authorized by AECOSAN as a technological adjuvant and certified as an input for organic agriculture.

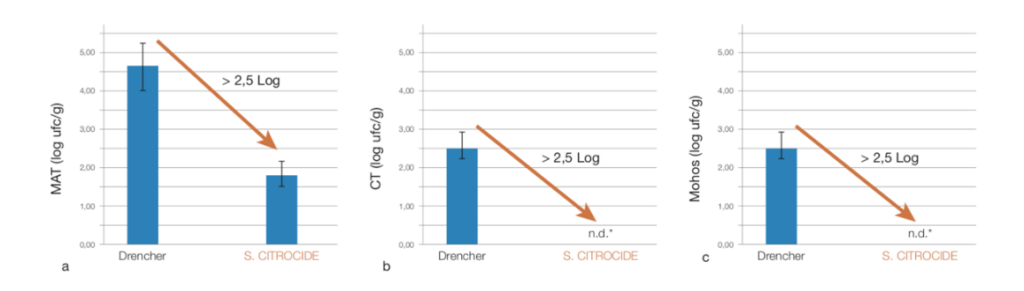

In citrus fruits, the CITROCIDE® SYSTEM acts as a "firewall", turning the washer into a real critical control point to avoid cross-contamination, improve food safety and reduce surface contamination, thus avoiding losses due to rotting of fruits and vegetables.

The CITROCIDE® SYSTEM is equipped with a computer program that allows it to record the relevant information of the dosing process, ensuring a detailed traceability of the process. The continuous measurement of the concentration of Citrocide® in the wash water and its automatic dosing allow us to guarantee the disinfection of the broth and its recirculation, drastically reducing the consumption of water and product, thus contributing to reduce the water footprint of the industry.

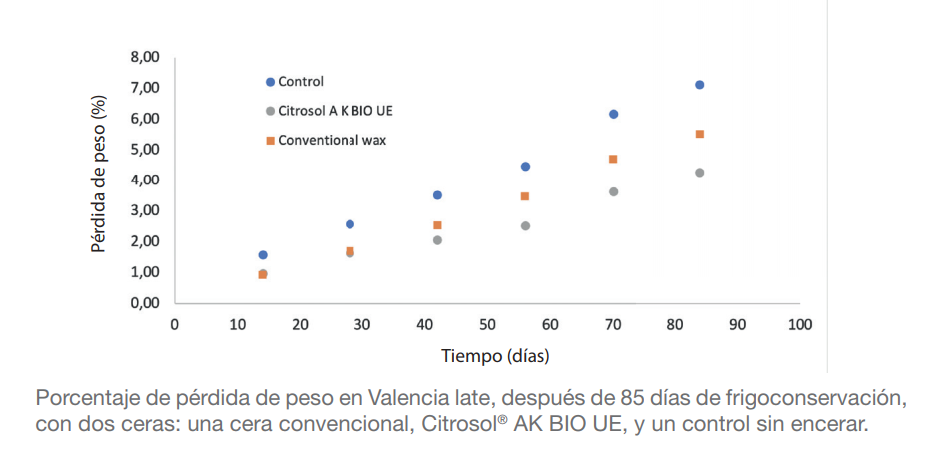

3.- CITROSOL® AK BIO EU gives a natural shine and excellent weight loss control. The appearance of organic citrus fruits waxed with CITROSOL® AK BIO UE can be compared to that of conventionally grown citrus fruits.

Due to its composition, with total absence of any ingredients of animal origin, CITROSOL® AK BIO EU also meets the requirements of vegan consumers.

Abundant scientific literature establishes how control over weight loss gives the fruit protection against chilling injury blemishes and skin fatigue. The excellent weight loss control of CITROSOL® AK BIO UE, and its effect on respiration, delay fruit aging.

Our formulations Citrocide® PC and Citrocide® PLUS are broad-spectrum biocides that control fungi, bacteria, yeasts and viruses. Their decomposition products are water and acetic acid, substances that are environmentally friendly and harmless to human health. Its use is authorized by AECOSAN as a technological adjuvant and certified as an input for organic agriculture.

In other fruits and vegetables (tomatoes, peppers, avocados, peeled garlic, sweet potatoes, persimmons, mangoes, etc.), as well as in the minimally processed food industry (IV range), the CITROCIDE® SYSTEM acts as a "firewall", turning the washing machine into a Critical Control Point (CCP) to avoid cross-contamination, improve food safety and reduce surface contamination, thus avoiding losses due to spoilage of these products. In the minimally processed food industry (IV range), the CITROCIDE® SYSTEM avoids the need to use chlorinated disinfectants to maintain the washing water in hygienic conditions and on the other hand, as shown in Figure 1, it performs a pre-cut disinfection of the fruit surface that greatly increases its shelf life.

The CITROCIDE® SYSTEM is equipped with a computer program that allows it to record the relevant information of the dosing and control process, ensuring a detailed traceability of the process. The continuous measurement of the concentration of Citrocide® in the wash water and its automatic dosing allow us to guarantee the disinfection of the broth and its recirculation, drastically reducing the consumption of water and product, thus contributing to reduce the water footprint of the industry.

Cleaning and disinfection

Good daily maintenance, cleaning and disinfection of the elements of the processing lines and machinery is essential, especially of the cold rooms, production and storage premises (walls, ceilings and floors, including drainage grids and drains) and, after use, of the elements linked to transport: crates, pallets, containers and trailers.

The establishment and application of a correct Cleaning and Disinfection (C&D) program in the industry leads to avoid the risk of cross-contamination by microorganisms pathogenic to human health.

In this sense, the cleaning and disinfection of cold rooms is crucial because they can be a reservoir of pathogenic microorganisms.