Citrus

First treatment

The application of the most appropriate postharvest treatments1, as a rule within the first 24 hours after harvest, is the main strategy to control rot, the main cause of postharvest losses in citrus fruits.

This treatment is usually applied in Drencher2, but if the fruit is pre-calibrated, it is carried out in the Drench on line. Fungicide treatments in aqueous medium are the best to achieve a perfect treatment of the fruit, with efficiencies that practically reach 100%.

With the CITROSOL VERTIDO CERO® SYSTEM3 and our technical support4, we are able to maintain the initial efficacy of the treatment in drencher, online drencher and basin, since it keeps the fungicide broths unaltered and the residue levels homogeneous.

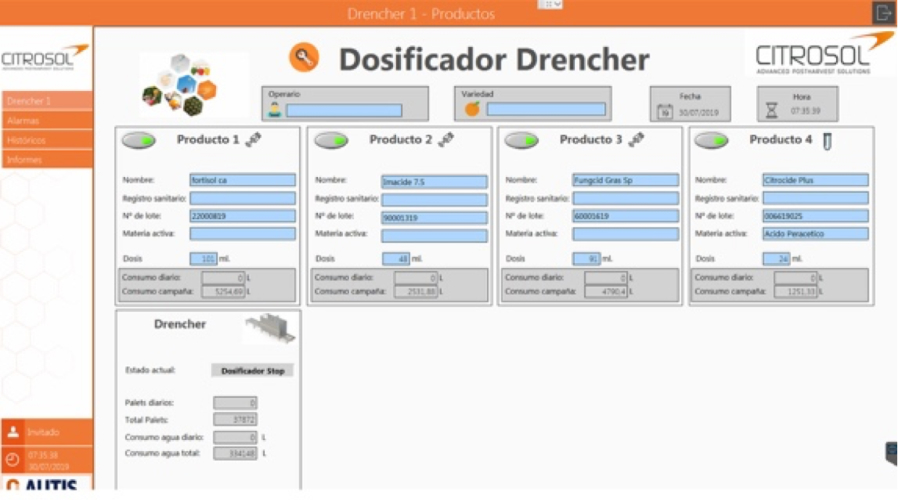

1.- Variability in application results in variable results in rot control and in the level of residues in the fruit. Our CITROSOL DS dosing equipment maintains unaltered the initial efficacy of the treatment broths.

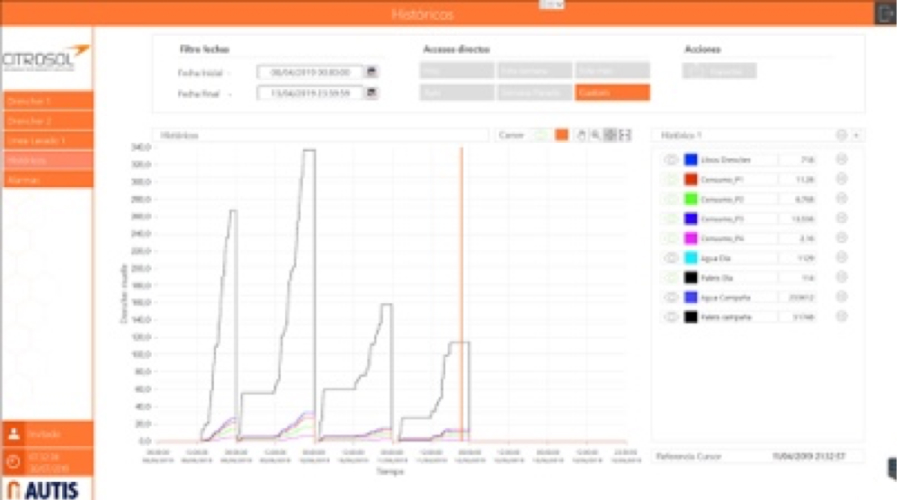

It is also connected to the CITRODATA platform for the management and recording of process variables in real time (treated pallets, fungicide, coadjuvant and biostimulant consumption, water consumption, etc.), offering record reports and traceability.

2.- Drenchers allow the treatment of fruit in boxes on pallets or directly in bins. The wetting is achieved by means of waterfalls that by overflowing obtain a continuous water sheet with sufficient flow to treat all the fruit.

The treatment can be applied directly on the line, with the Drench on line, after dumping and after passing through the washing machine. The treatment is applied by means of stainless steel waterfalls that generate a continuous sheet of water that ensures the complete wetting of all the fruits.

The CITROSOL VERTIDO CERO® System allows the recovery of the broth from the drenchers and the reduction of suspended solids, without affecting the concentrations of fungicides, coadjuvants and biostimulants, which we manage to keep constant.

To maintain the initial efficacy of the fungicide treatment in Drencher, Drench on line and pond, it is essential that the fungicide broths remain unaltered, so that we also achieve homogeneous residue levels.

This system eliminates rotting problems due to cross-contamination in the drencher by keeping the treatment broth clean. It also solves an important environmental problem, as it avoids the dumping of the fungicide broth used, allowing it to be reused season after season.

ZERO DISCHARGE SYSTEM CITROSOL

DRENCHER'S BROTH 4865 TREATED PALLETS

CONVENTIONAL SYSTEM

DRENCHER'S BROTH 200 TREATED PALLETS

4.- Our know-how and the follow-up we carry out, guarantee an adequate management of the first treatment, whether it is carried out in a drencher, Drench on line or pond.

For this purpose, in addition to our laboratory service, we have the EASY KIT®, a tool that allows us to obtain these results immediately on site.

On-line treatment

Washing1 of fruit and vegetable products is a critical point for spoilage control and food safety, and must ensure that pathogenic microorganisms do not accumulate in the washer. This will prevent cross-contamination and contribute to excellent spoilage control.

Waxing2 of citrus fruits is a necessary process, since washing in particular removes the natural wax from the fruit. Therefore, the application of a coating makes it possible to control weight loss, delay aging by reducing transpiration and respiration, and provide gloss.

1.- The post-harvest washing of fruit and vegetable products is a critical point for spoilage control and food safety. Citrocide® PC and Citrocide® Plus are broad spectrum biocides that control fungi, bacteria, yeasts and viruses. Their use is authorized by AECOSAN as a technological adjuvant and certified as an input for organic agriculture. Correct washing contributes greatly to the control of resistance to fungicides in use.

The CITROCIDE® ONLINE acts as a "firewall", turning the washer into a Critical Control Point (CCP) to prevent cross-contamination, improve food safety and reduce surface contamination that would reduce the shelf life of citrus.

Waxing is carried out once the fruit is dry, with a system composed of rotating heads and brushes that allow a homogeneous application of the coating.

Our Ultra Low Volume (ULV) systems incorporate the tipping control, which allows measuring the flow of fruit in the tipper and adjusting the amount of wax to be applied.

Additionally, we can incorporate the CITROVISION® SYSTEM that measures the fruit flow with artificial vision cameras and homogenizes the wax dosage in real time.

Among our citrus waxes, CITROSOL® SUNSEAL UE stands out for long distance shipments. It offers excellent control of weight loss and its film is very resistant to strong condensation at the exit of cold temperatures, such as those that occur after the opening of containers.

It is also a low-temperature drying wax that reduces energy consumption, thus reducing our customers' carbon footprint and contributing to the fight against climate change.

Degreening / Preservation

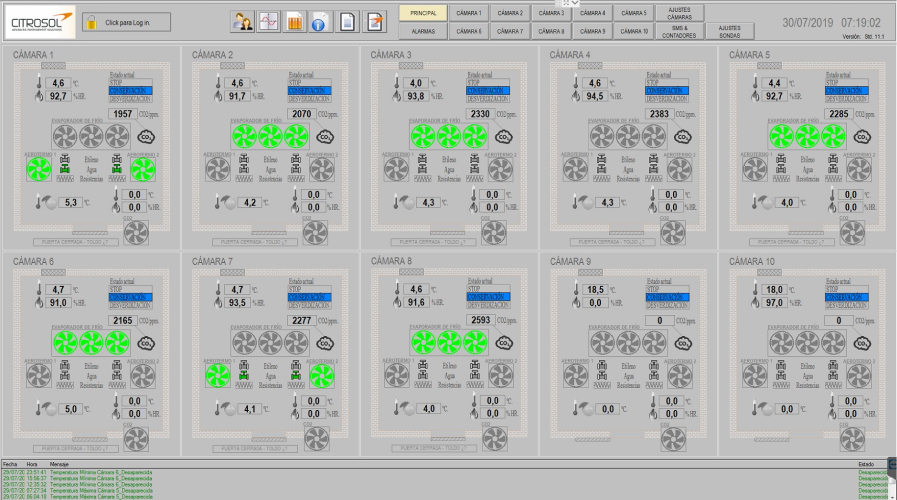

Control of degreening and cold storage chamber parameters1 are critical, they are of great importance to delay senescence, avoid the appearance of rotting and thus reduce food wastage.

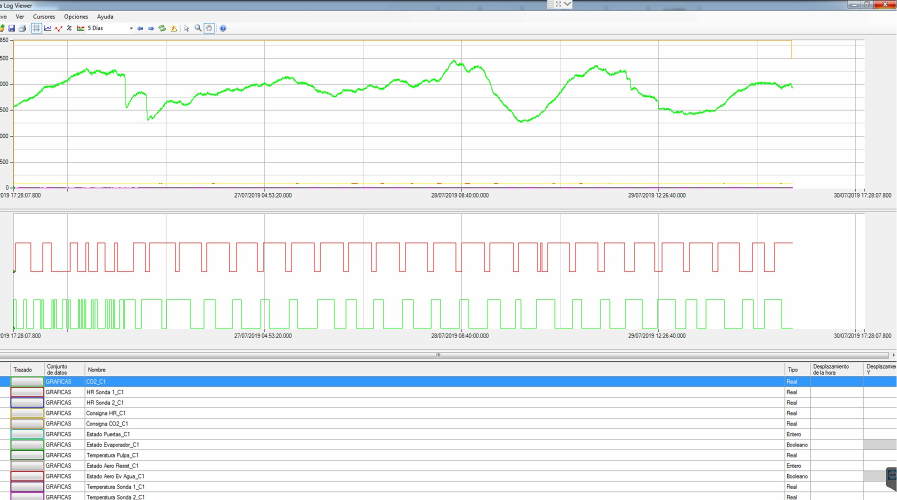

1.- Our technical team makes the recommendations of the degreening or cold storage conditions: temperature, ethylene andCO2 concentration, relative humidity and maximum storage time. The CITROGAS SYSTEM allows the automatic control of the atmospheric conditions of the chambers during degreening and cold storage.

The data acquisition system has been designed to monitor, control and record the history of these processes, guaranteeing traceability.

In addition, we carry out on-site verifications of the conditions of the chambers and the stored fruit during the conservation and degreening periods, measuring pulp temperature, environmental contamination, etc.