Vegetables

First treatment

In vegetable postharvesting, washing1 is a critical point for spoilage control2 and food safety3 because it is where pathogenic microorganisms are controlled.

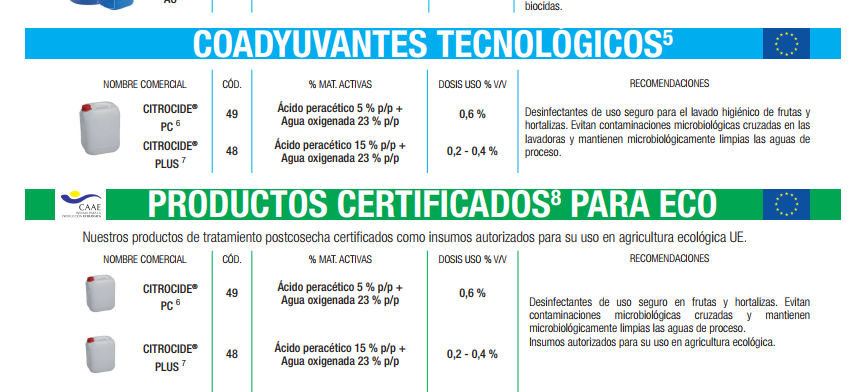

The post-harvest washing of fruit and vegetable products is carried out with the CITROCIDE® SYSTEMS, which monitors and controls the concentration of Citrocide® PC and Citrocide® PLUS in the washing water, always maintaining maximum efficiency. The continuous measurement and automatic dosing of the latter allows us to guarantee the disinfection of the broth and its recirculation, reducing the consumption of water and product, contributing to reduce the water footprint of the industry.

The CITROCIDE® SYSTEM acts as a "firewall", turning the washer into a Critical Control Point (CCP) to prevent cross-contamination, improve food safety and reduce surface contamination that reduces the shelf life of vegetables.

Its use is authorized by AECOSAN as a technological adjuvant and certified as an input for organic agriculture.

2.- Rotting is one of the main causes of complaints at destination. The effectiveness of the system has been demonstrated at industrial level in different fruit and vegetable plants, making it clear that not washing is not a viable alternative.

The Citrocide® System acts by effectively inactivating all types of microorganisms, both pathogens potentially dangerous to human health and those that cause spoilage, reducing and even eliminating microbiological contamination on the surface of vegetables, in the wash water and in the washing machine.

Our formulations significantly reduce surface contamination by bacteria, fungi and yeasts.

The Citrocide® System acts by effectively inactivating all types of microorganisms, both pathogens potentially dangerous to human health and those that cause spoilage, reducing and even eliminating microbiological contamination on the surface of vegetables, in the wash water and in the washing machine.

Our formulations significantly reduce surface contamination by bacteria, fungi and yeasts.

Conservation

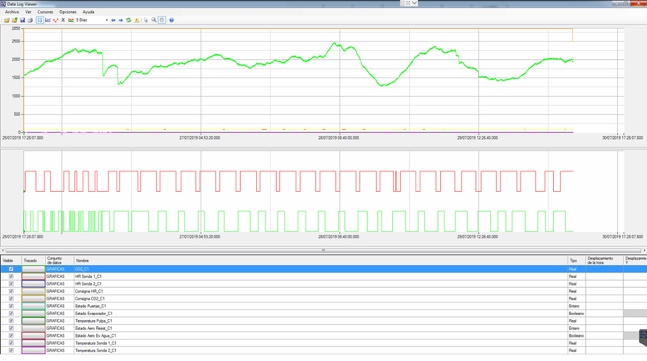

Control of cold storage room parameters1 is critical in postharvest to delay senescence, prevent the occurrence of spoilage and thus reduce food waste.

1.- Our technical team carries out the recommendations and protocols of the cold storage conditions: temperature, CO2 concentration, relative humidity and maximum storage time . The CITROGAS SYSTEM allows with a single equipment the automatic control of the atmospheric conditions of the chambers during storage.

The data acquisition system has been designed to monitor, control and record the history of the entire process, guaranteeing traceability.

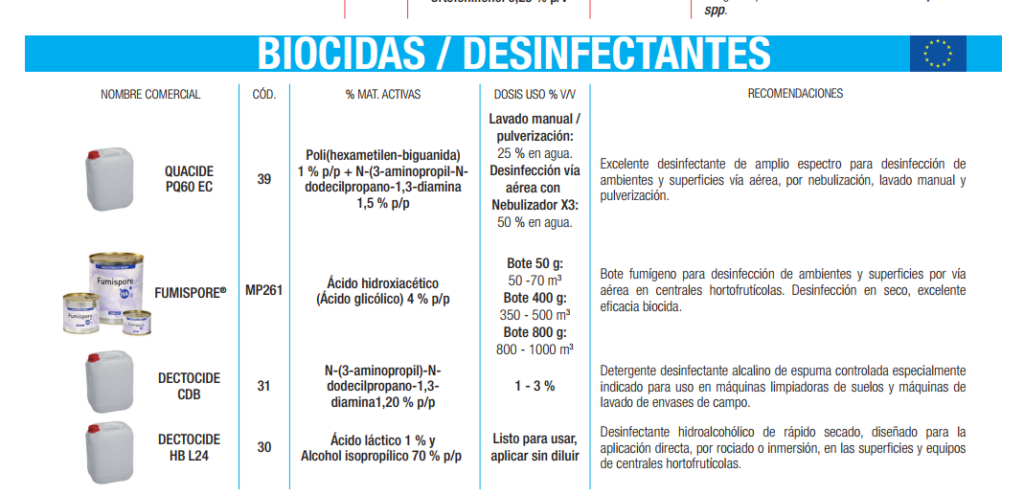

Cleaning and disinfection

Decreasing inoculum levels1 in the different areas of the Central Fruit and Vegetable Processing Plant, as well as in the crates2 is essential for the control of spoilage.

1.- The maintenance of the hygiene of the fruit and vegetable plant (CH) and its elements is essential for the control of rotting in vegetables.

The establishment and application of a correct Cleaning and Disinfection (C&D) program in the plant leads to a significant improvement in the results of rot control and avoids the risk of cross contamination by microorganisms pathogenic to human health.

2.- Field containers can constitute an important reservoir of pathogen inoculum. Any L&D program should include an efficient protocol for their washing and disinfection.

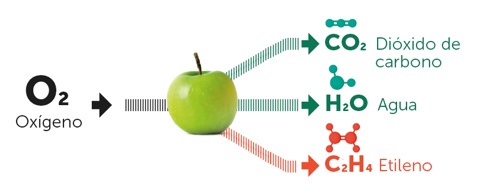

Transportation

From the time of shipment and during transport, it is necessary to keep in mind that vegetables are living beings that continue to breathe after harvest. As they breathe, they produce carbon dioxide (CO2), water (H2O) and ethylene (C2H4). The elimination of ethylene1 in the environment of the fruit and vegetable plant and in transport provides us with additional safety for good arrivals at destination. In addition, ethylene accumulations are often very harmful to vegetables.

Ethylene is a gaseous hormone that all vegetables synthesize. This hormone regulates the processes associated with ripening and senescence of fruits and vegetables.

The accumulation of this gas causes accelerated ripening, wilting and, in green vegetables, loss of chlorophyll, thus affecting the loss of quality and shortening their shelf life.

Ethylene is eliminated through an absorbent that also absorbs the volatile organic compounds responsible for odors and slows ripening.